Mainly just pictures for now as it takes way to long to do a post for everything and I got work to do. I'll go into details as the weekend ends. The job I'm on now is a nice 2 hour drive each way so that makes for nice 12-14 hour days and only weekends for wrenching so don't want to waste to much time typing on a Sunday morning.

*edit* Weekend is over so lets add some words to the pictures.

Looked at way too many hardline pictures so I tried my hand while waiting for bags and bars. Bought a Rigid 3/8 inch bender off of Ebay to use for bending lines. The thing worked great and after a few tries got pretty good at putting bends where they needed to be. Spend some time with the buffing wheel and sand paper after reading and watching tutorials on You Tube. Got the tank pretty close to done, just got a little bit more polishing but figured it was going to get a bit dirty during install so I'm save the last polishing for after I get everything set right where I want it.

Using 3/8 SMC valves I got from The Gauge Store, on sale for $200. My first purchase for this extravaganza. Mounting the four fills on the tank, the rear two dumps will be mounted under the tank close to the bags and the front two will be installed under the fender well covers (not sure of the proper name.) All four corners will have flow control valves to control descent along with check valves. That way if I loose a line between the tank and the bag the bags should stay inflated.

Once i got to this point I temporarily installed the check valves where the lines exit the tank and added a schrader valve where the EDC will fill at. I had to see if those push-to-connect (PTC) fittings really worked. Filled it up to 100 PSI like the plumbers at work do when they test systems. It held for two days without one leak, guess they do indeed work. Oh, Used Locktite 545 thread sealant on all the threads, bought this from seller iwillgetitforu on Ebay. The PTC fittings are ASCO units I bought from fx_custumz on Ebay.

Here it is sitting in the trunk For some reason it looks crooked in both pictures but I checked and it's not

Getting the right size for the sub boxes was hard since I didn't just want square boxes. Not only are they triangular but they slope down from the front of the box (the side towards the back seat) to the end (the side were the trunk lock is) to meet the contour of the trunk lid. Not so sure I like where they are placed in the box now, in the middle would be more eye pleasing but not sure if they would fit there due to depth restrictions.

At this time everything in the trunk is just placed there. It all needs to be cleaned up, dialed in, little filler pieces made, boxes need to disassembled and glued and everything needs to be screwed down.

Bars and bags showed up from Thor Brothers (Suicide Doors) so I stopped work on trunk set up so I could get to work on suspension.

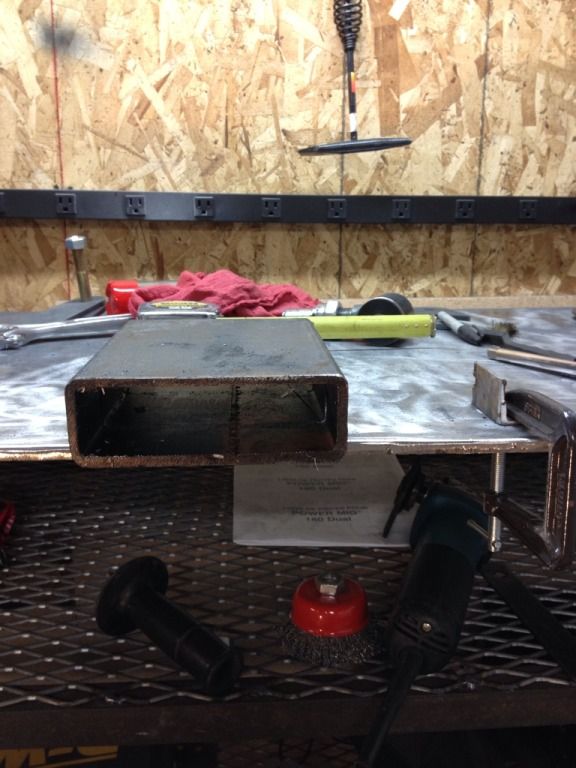

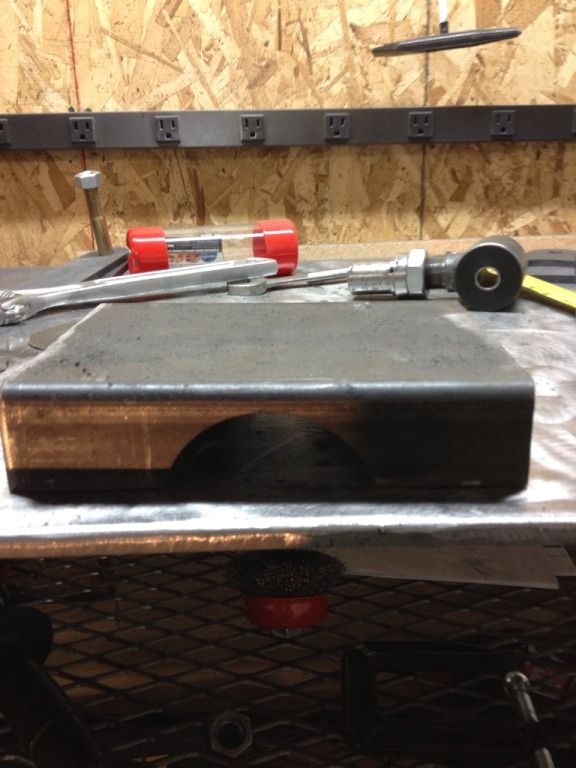

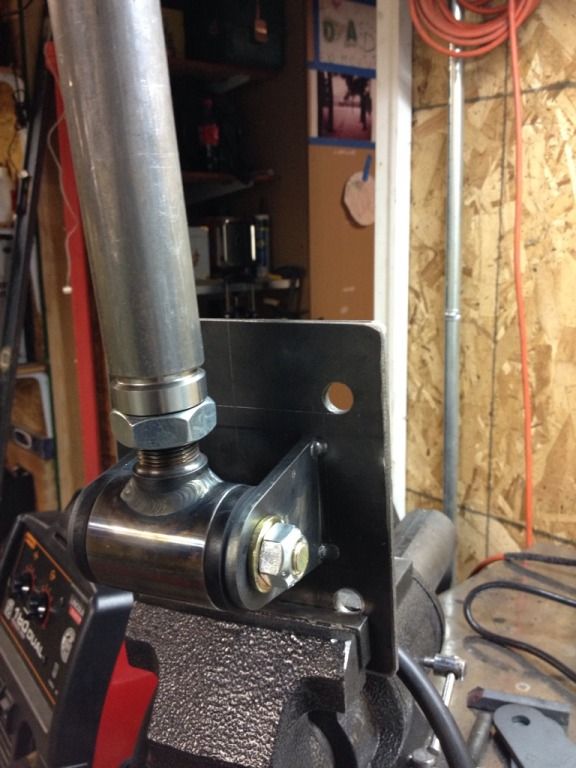

I made my own plates out of 1/4 inch steel to mount the lower bars in the stock leaf spring location. Bought new heavy duty 9/16 inch u-bolts, grade 8 washers and lock washers. After much measuring and re-measuring I bit the bullet and cut the bars to length and tacked the tabs to the plate.

Here it is mounted up without the Grade 8 stuff.

At this point I made the other bar and went to mount it. Turns out the axle got shifted a bit, not enough to do any harm but enough to make me get tired of the half-assed way I was using jack stands and a bottle jack to keep the rear end in place. So off came the one bar and I got out a 4 X 4 sheet of 3/4 inch plywood I found at work. Used some heavy duty shelving brackets, 1 X 4's and 2 X 2's and made me a rear end carriage to hold that thing in place. I know, kinda red neck but I do live one exit from the Idaho border so cut a guy some slack! Got out the tape and plumb bob to get the rear end centered and squared and pinion angle set(again.)

You can see here that at ride height with the pinion angle set I managed to get the rear bar fairly level to the ground. The next challenge is going to make the upper ones match while maintaining the correct length. Not knocking Mob Steel at all as I have no first hand knowledge of their product (I'm probably going to wish I just bought their kit by the time this is all said and done) but in the few pictures I've seen it doesn't seem like their upper bars are angled enough to locate the axle properly. I'm sure it's just the pictures but I'm thinking I got my work cut out for me trying to make room for the bags and the upper bars. Hope the exhaust fits after I'm done!

Working on upper bars today. Next weekend is a big one for my wife as she's rolling out here leadership conference to a few thousand people so I'll be tied up there. So far you're looking at about a months worth of work. With my wife traveling, two kids and my work schedule I don't have much time to work on this but will do updates when I can.